PRODUCTS

Around-the-clock customer care with a cycle of service.

From our groundbreaking Thunder Series, to the industry icon PZ-11, discover what operators worldwide have known for decades – nothing works harder for longer than a GD Energy Products Pump.

Pump University, GD Energy Products’ mobile classroom that travels to a customer’s facility and trains employees how to properly maintain pumping equipment

Backed by our state-of-the-art repair facilities, we offer a comprehensive range of on-site services. From power and fluid end inspections and repairs, to hands-on training; we have you covered. Our team of expert technicians can be deployed to your job-site, where and when you need them.

With service centers and manufacturing facilities across the nation and around the globe, no matter where you are or how remote the location, GD Energy Products will be there for you.

Parts on Demand let you manage your replacement parts inventory at your regional location, pump site, or even via GD Energy Products Parts on Demand mobile trailers.

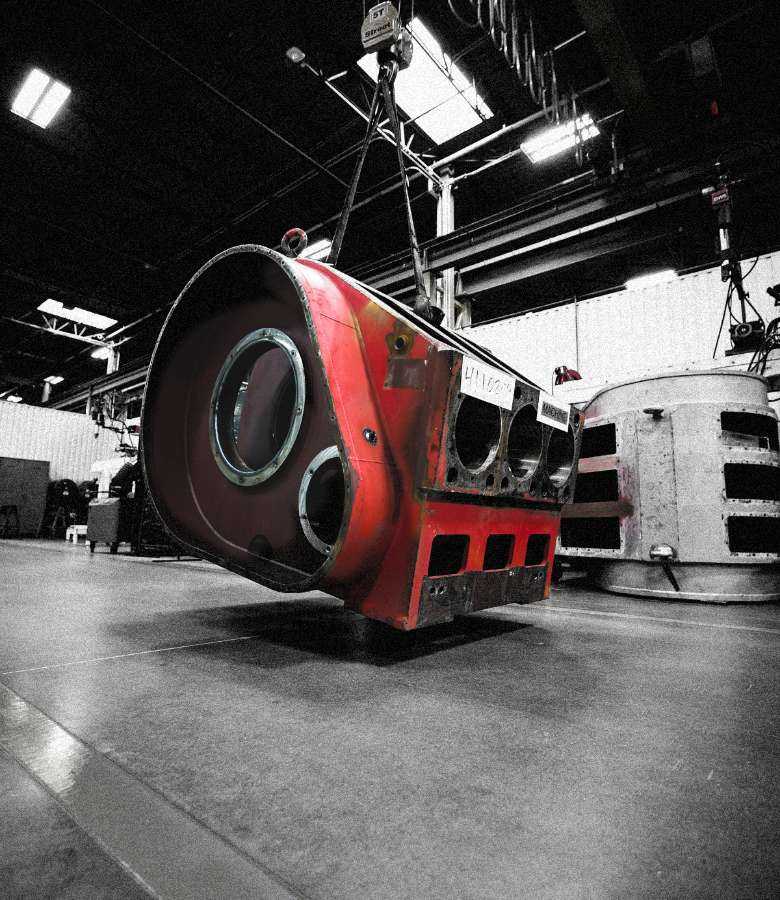

Our state-of-the-art repair facilities combine world-class equipment with over 150 years of industry leading expertise, to provide our customers with a comprehensive range of services. If you can’t come to us, we can bring our legendary expertise to you, using our full range of on-site repair and field service offerings.

STAYING FOCUSED ON YOU.

We know what downtime costs our clients. Our service infrastructure has the reach and warehouses ready with the spare parts you need – backed by knowledgeable employees with autonomy to initiate any service or repairs on the spot.

In our industry, the work itself is hard enough. So, we provide solutions that maximize simplicity and cost effectiveness, with a service network that helps ensure that the right parts and services are never far away.

To provide the best outcomes for our customers, we set high standards for all of our products and services, and never stop developing more efficient or effective solutions to fit their specific needs.

Backed by 160 years of development, our pumps are the most powerful and highly engineered on the market – the standard bearer for safe, efficient power production at lower RPMs.